Blasting

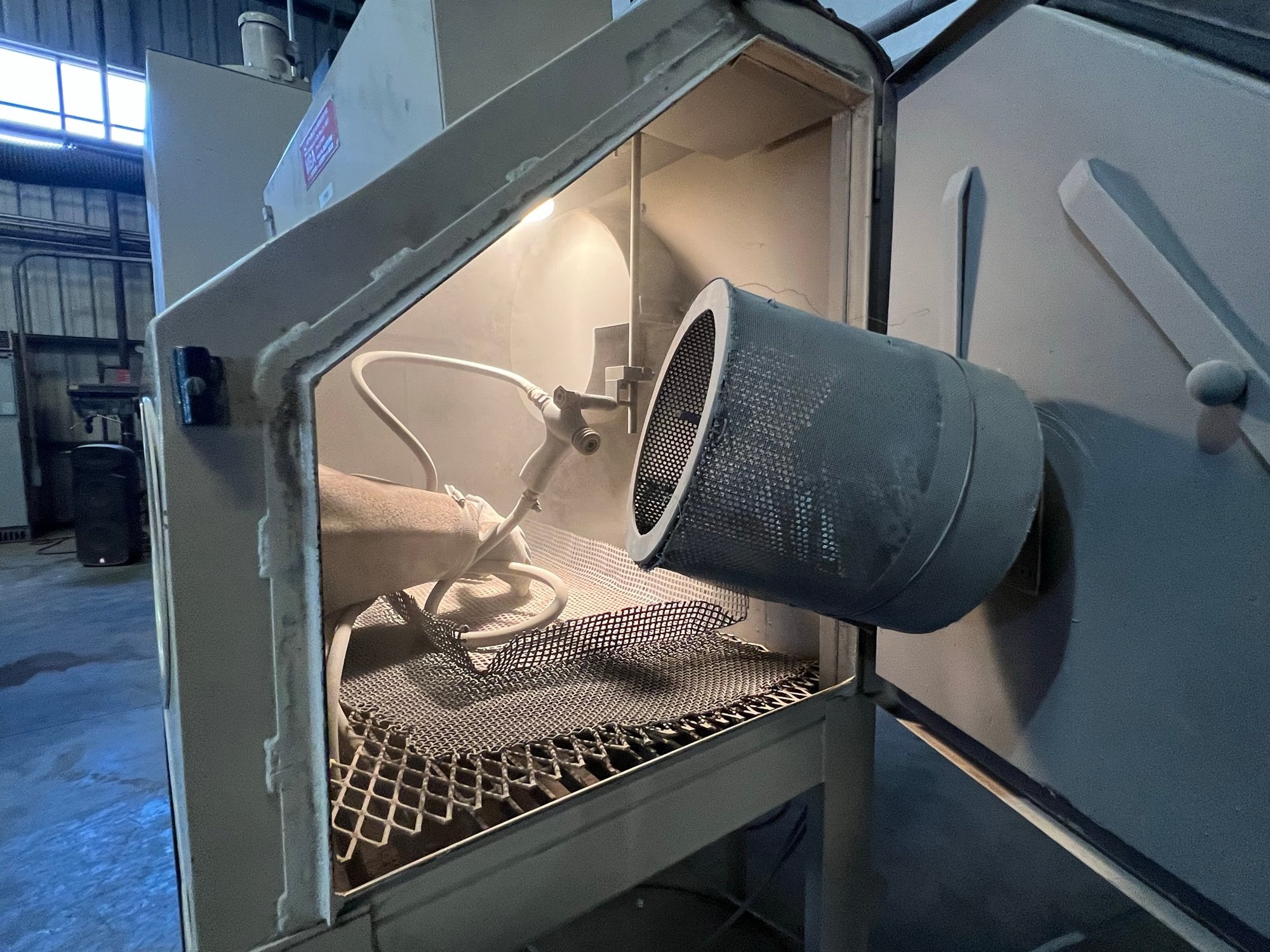

What is Blasting?

Blasting is the process of cleaning or removing any heat treating scale or discoloration from parts. Blasting can also be used to achieve a uniform finish on parts that have not been through a heat treating operation. This process is done per request by the customer. Typically, items that go through neutral hardening are required to be blasted. Sand, glass, steel shot, or aluminum oxide medias are used in a pressurized system to achieve the desired surface finish. Each media is per the customer's request. This blasting operation can be performed in multiple different techniques such as tumble blast, roto blast, or hand blast.

-

Alloy Steel

-

Copper Alloys

-

Stainless Steel

-

Aluminum

-

Nickel Alloys

What Industries require Blasting?

Manufacturers for all industries, including Aerospace, Automotive Racing, Molding, etc. use heat treating processes to modify metals and alloys. Every time you see a piece of metal or plastic, it has most likely been through a heat treating process that has included blasting, from the smallest screws to rocket ship tips and earth mover chassis. Manufactured pieces of metal or plastic have strength and performance requirements that can be met by heat treating and blasting procedures.

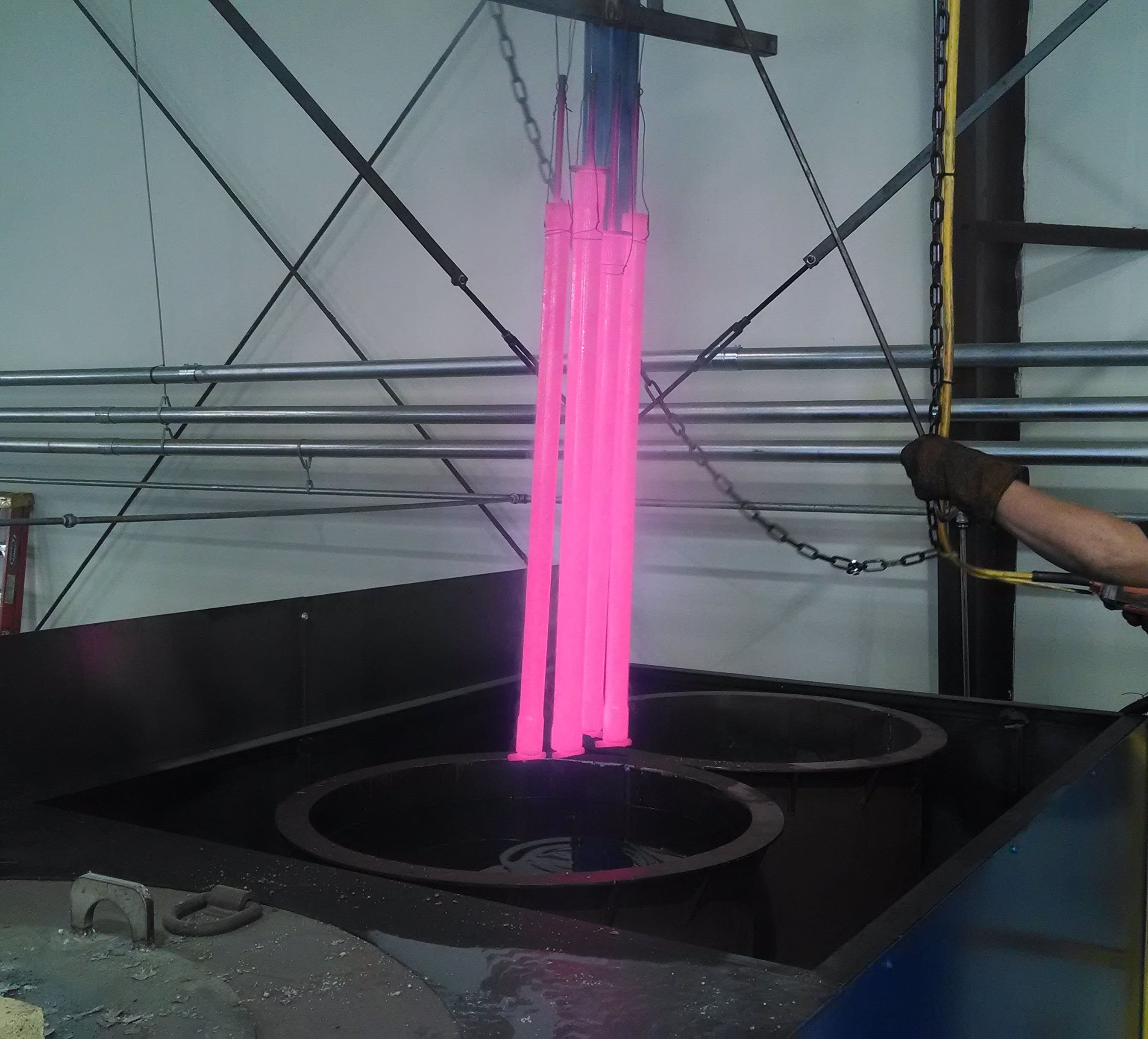

Neutral Hardening

A process using oil & salt quenching to harden steel without any oxidation or scaling. This process also hardens without adding or taking away carbon from the steel.

-

Alloy Steel

Our Quality Policy

National Thermal Processing shall deliver the services and products that meet the customer's requirements. National Thermal Processing commits to continuous improvements by training its people, upgrading equipment, eliminating nonessential practices, and creating a quality conscious environment.

Request a Quote from Our Team

Hardness Testing

After each order is treated, our team performs a hardness inspection to verify the metal meets the customer's specifications.

-

Alloy Steel

-

Copper Alloys

-

Stainless Steel

-

Aluminum

-

Nickel Alloys

-

Composites